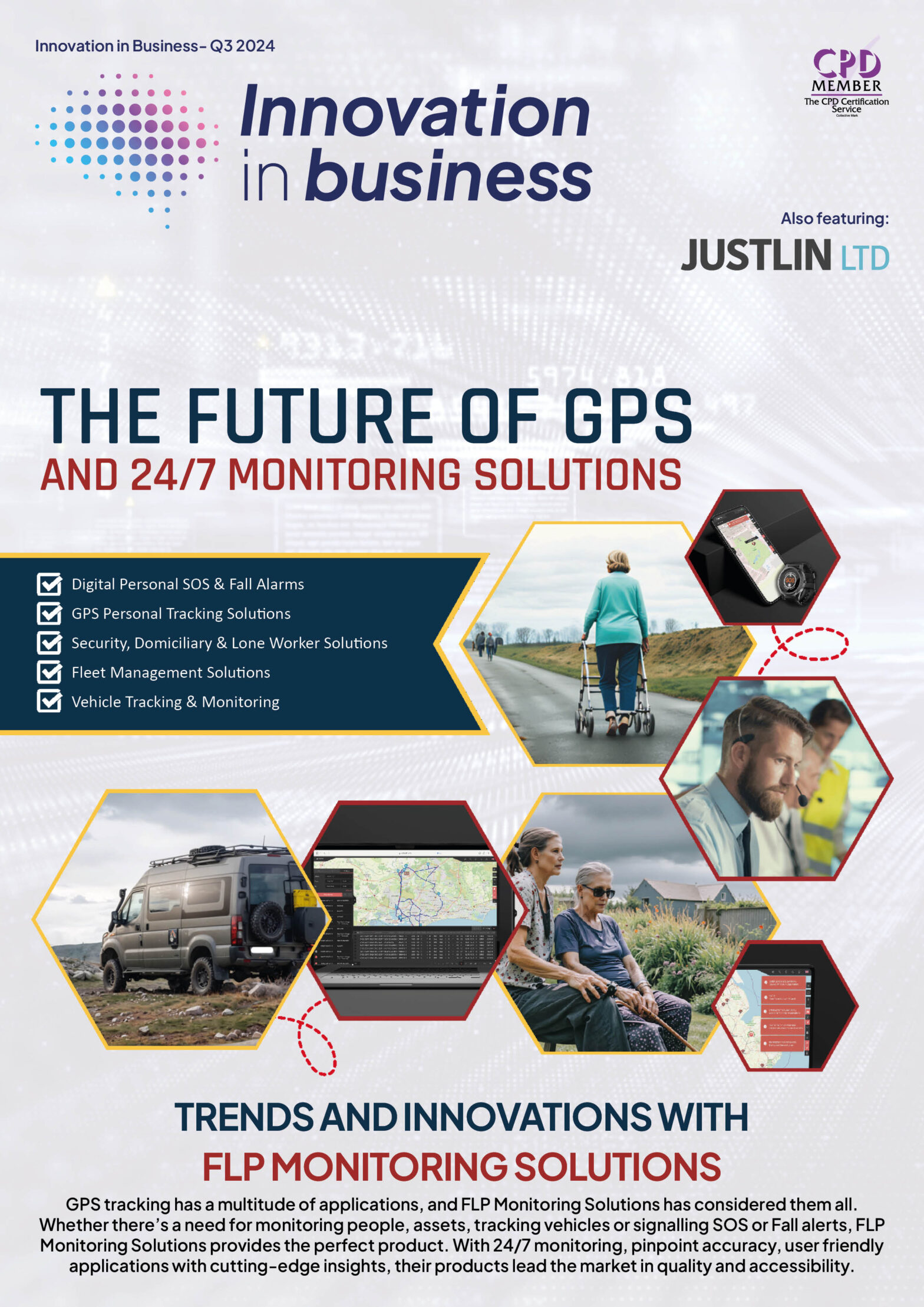

How Businesses Are Advancing Workplace Safety with Modern Tech

https://images.unsplash.com/photo-1589325999888-06f95cc11f61

In the fast-changing landscape of today’s workplaces, ensuring safety is crucial. The figures are alarming: in the U.S., a worker loses their life every 96 minutes. Nearly 5,500 fatal work injuries were reported in 2022, marking a troubling 6% increase from the previous year. These figures highlight an urgent need for innovation in safety practices.

The National Safety Council launched the Work to Zero campaign in 2019 in response to this mounting worry. The initiative aims to educate employers on leveraging modern technology to reduce workplace fatalities.

As we navigate this era of technological advancement, businesses are increasingly turning to cutting-edge solutions to enhance workplace safety. From wearable tech and artificial intelligence to robotics and smart sensors, modern innovations are transforming how companies protect their employees. Notably, 83% of workers are open to embracing these new safety technologies, recognizing their potential to create safer work environments.

This article explores how businesses are enhancing workplace safety with modern technologies, covering their benefits, challenges, and future trends.

Wearable Technology

Wearable technology is significantly enhancing workplace safety by offering real-time monitoring and feedback, which is crucial for preventing accidents and maintaining health.

According to the US Government Accountability Office (GAO), the functionality of wearables varies based on their technology. For instance, exoskeletons and powered gloves provide physical support, alleviating strain on workers’ shoulders, hands, or backs during repetitive tasks like lifting or gripping.

Smart helmets are another groundbreaking development. These helmets integrate physiological and environmental sensors with GPS trackers, providing comprehensive protection. They can detect falls and alert both employees and medical teams to immediate hazards such as excessive heat or high humidity. Similar to this, ergonomic sensors placed on the arm, hip, or back, can track motions and identify risky behaviors like improper lifting techniques.

Furthermore, biometric wearables track vital signs like body temperature and heart rate. They alert both workers and supervisors to signs of fatigue or heat stress before these issues become more serious.

These wearables not only offer real-time alerts but also generate valuable data for training and preventive measures. By equipping workers with these advanced tools, businesses can proactively address safety issues, reduce injury rates, and foster a more secure working environment.

How do wearable devices impact employee productivity in addition to safety?

Wearable devices enhance employee productivity by providing real-time feedback and monitoring, which helps optimize work techniques and reduce downtime caused by injuries. Additionally, the data collected can be used to streamline processes and improve overall efficiency, leading to better performance and fewer disruptions in workflow.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming workplace safety by enabling advanced real-time monitoring and predictive analytics. The University of South Florida notes that AI systems with machine learning can analyze safety data in real-time, spotting hazards before accidents occur. This proactive approach allows for swift corrective actions and helps prevent incidents by addressing risks early.

AI also enhances behavior recognition, detecting when workers deviate from safety protocols and offering targeted training opportunities. Additionally, AI systems improve incident response by analyzing visual data to support timely and effective actions. With its ability to analyze large datasets and minimize biases, AI is crucial in promoting fair and effective safety practices in the workplace.

What challenges does AI face in forecasting workplace safety risks?

AI’s challenges in forecasting workplace safety hazards stem from its dependence on past data, which might not cover new or emerging risks. Additionally, it may struggle with identifying unforeseen dangers and accurately reflecting complex human actions and environmental factors. Despite these drawbacks, AI still provides valuable early warnings and insights that can significantly enhance proactive safety measures.

Robotics and Automation

Robotics and automation are transforming workplace safety by handling high-risk tasks and reducing human exposure to dangerous conditions. Advanced robotic systems are increasingly used in manufacturing and hazardous environments, automating repetitive and dangerous tasks to minimize human error and injury.

These robots handle tasks like lifting heavy materials and inspecting equipment in dangerous areas, significantly reducing accidents and enhancing safety.

In industries such as firefighting, robotics play a crucial role, especially in high-risk environments like aircraft, chemical plants, and naval facilities. These areas are prone to severe fire hazards and exposure to hazardous materials such as AFFF (Aqueous Film-Forming Foam).

Firefighting robots can operate in extreme conditions, shielding human firefighters from dangerous exposures and reducing health risks linked to AFFF. Many veterans have noted these risks in VA claims for AFFF exposure, emphasizing the need for robotic intervention to minimize such hazards.

TorHoerman Law states that former firefighters, veterans, and retirees exposed to AFFF may be eligible for the AFFF MDL. They could potentially receive financial compensation for any related health issues or injuries.

Internet of Things (IoT) and Smart Sensors

IoT devices can be embedded in equipment and work environments to continuously track various conditions, such as temperature, humidity, and air quality. These smart sensors detect potential hazards and alert workers and management before an incident occurs, allowing for proactive safety measures.

Additionally, IoT-connected devices can monitor worker movements and machinery, ensuring that safety protocols are followed and reducing the risk of accidents. The ability to collect and analyze data from these sensors also enables businesses to identify patterns and implement long-term safety improvements.

Virtual Reality (VR) and Augmented Reality (AR)

Virtual Reality (VR) and Augmented Reality (AR) are revolutionizing workplace safety by offering immersive training experiences and real-time hazard awareness. VR allows workers to engage in simulated environments where they can practice safety protocols and respond to potential emergencies without any real-world risks. This technology is especially useful for training in high-risk industries like construction and manufacturing, where hands-on experience is crucial but risky.

AR, on the other hand, enhances workplace safety by overlaying real-time information directly into the user’s field of view. Technology Magazine reports that companies like Skanska use AR to identify safety risks on job sites, which helps reduce accidents and improve safety compliance.

In manufacturing, firms such as Boeing and Lockheed Martin use AR to show crucial machine status and safety procedures. This technology helps workers identify and avoid hazards more effectively. Additionally, companies like Vuzix and RealWear produce rugged AR headsets for industrial settings, delivering essential safety information without disrupting workflows.

What are the limitations of VR and AR in safety training and hazard assessment?

VR and AR in safety training and hazard assessment have limitations, such as high implementation costs and the need for specialized equipment. Additionally, these technologies may not fully replicate real-world complexities, potentially leading to gaps in training and hazard recognition.

Challenges and Considerations

High costs of implementation, especially for small businesses, can be a barrier. Additionally, the integration of new technologies requires extensive employee training and adaptation, which can slow down initial productivity. Increased use of smart sensors and AI raises concerns about potential misuse or breaches of sensitive data.

Balancing technological adoption with these considerations is crucial for businesses aiming to enhance safety without compromising other critical aspects.

Transforming Workplace Safety Through Modern Tech

Incorporating modern technology into workplace safety strategies is transforming how businesses protect their employees. Wearable devices, AI analytics, IoT, and VR training are lowering accident risks and promoting a safety culture.

As businesses navigate the challenges and opportunities of these advancements, they are setting new standards for workplace safety. These efforts ultimately ensure a safer, more efficient environment for all.

Technology

25 March 2025

Ransomware-As-A-Service Variants on the Rise With Critical Infrastructure Providers at the Greatest Risk

Business Advice

25 March 2025

Claims Processing Automation: How Insurers Can Cut Costs and Improve CX

Technology

18 March 2025

Secret Signs Your Internet Security Has Been Compromised